When you have defects, variations, imperfections or failures in your processes and systems, finding their causes is imperative. The only way to come up with solutions for faulty processes is to know where the problem lies.

Root cause analysis tools can help you determine underlying challenges. The Fishbone Diagram is one of the most common applications used for root cause analysis. Also called the Ishikawa Diagram, the tool was popularised in the 1960s as a quality control measure that companies now use in various capacities to identify bottlenecks in different areas.

When looking for a way to pinpoint the challenges in your systems, then the Ishikawa Diagram is worth considering. However, you must first learn how it works and its value.

What is a Fishbone Diagram?

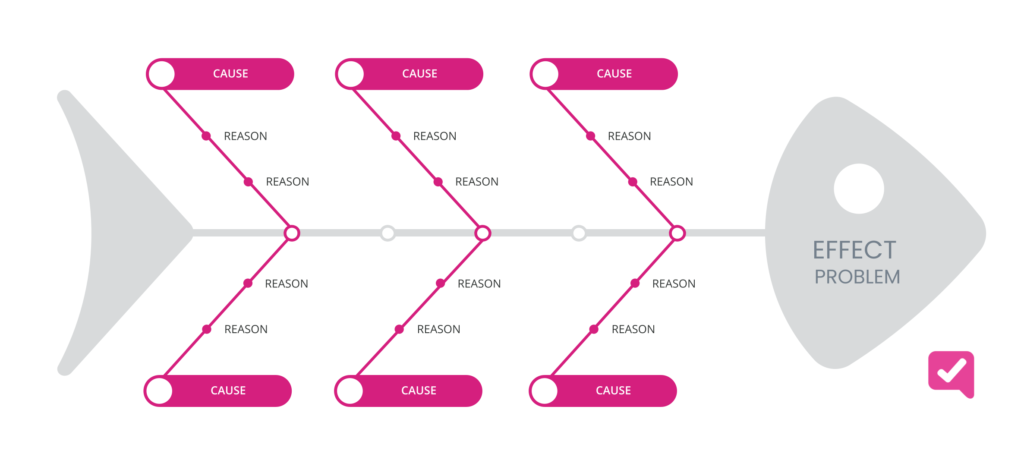

As the name suggests, the tool resembles a fish skeleton. When drawing the figure, the root problem is at the head of the fish while the causes fit into the spine. With the head facing right, the causes shoot off to the left, looking like fish bones.

You can have major causes as the main branches while minor ones form the sub-branches. The diagram can have as many branches as the project requires. Identifying all the reasons for the problems faced allows managers to search for the best solutions.

Fishbone Diagram History

Fishbone diagram was created by Dr. Kaoru Ishikawa (1915-1989)

Although the concept of the Fishbone became popular in the 1960s, its origins go back to the 1920s. In the 1960s, a Japanese quality management expert Kaoru Ishikawa applied the tool to deal with challenges at the Kawasaki shipyards. The same system was used during the design of the Mazda Miata sports car, factoring all aspects like an armrest for the driver. Even though the tool was applied to manufacturing, it is suitable for a host of other uses.

The Fishbone diagram was not Ishikawa’s only created in the area of quality. He also developed the idea of “quality circles.” A quality circle of people to analyse and solve business problems. It is believed to have been developed from a lifelong interest in the Deming circle: Thus the quality circle theory is a direct influence from Deming’s PDCA Plan-Do-Act-Check cycle.

What is another name for the fishbone Diagram?

Fishbone Diagram has many names that you may not realise are all the same sort of diagram.

The first is named directed after its creator Dr. Kaoru Ishikawa.

- Ishikawa Diagram

- Fishbone diagrams

- Herringbone Diagrams

- Cause-and-Effect Diagrams

- Fishikawa

How does a fishbone diagram work?

The main aim of the process is to try to solve the problem.

A Fishbone diagram is a way to visualise potential causes of a problem as the name suggests, it’s named after a fish due to the diagram mimicking a fish skeleton.

The problem you are trying to resolve is placed in the fish’s head.

The causes extend along to the bones of the fish skeleton; the ribs act as branches that denote major causes, then the sub-branches branch off the causes and help identify root causes. These add to the bones of the fish skeleton.

Don’t feel restricted by the number of fishbones as branches can go off to as many levels as you require to determine the underlying cause of the problem.

What does a fishbone diagram display? It is a way to identify possible causes of a problem and enables you to separate ideas into categories.

Example Fishbone Diagram

How to Create an Ishikawa Diagram

The fishbone figure makes it easy to define the underlying issues that interfere with the optimal performance of processes. However, the tool is only effective if you know how to use it. Here are the four main stages of creating an Ishikawa Diagram.

Identify the Problem

Your fishbone figure starts with defining the specific problem that you are dealing with. Write down what it is, when it occurs, where and who’s involved. This problem should be in a box on the right-hand side. From that box, trace a horizons line running to the left.

Analyse the Primary Factors Involved

The next step is to find out what is causing the problem. These can range broadly depending on the challenges. You could have software that’s not working right, materials, employees, equipment, methods and so on. For each cause that you identify, draw a line off the main horizontal one. Label the branches accordingly.

Pinpoint Possible Causes

Discuss with your team the causes of the elements identified in step two. For example, if the issue is equipment, the cause could be poor maintenance. Add these causes as offshoots from the main factors. If a cause has multiple facets, then break it down.

Analyse the Diagram

Once the diagram is complete, you can evaluate it keenly to see where the real issues come in. Breaking down the causes makes it easier to tackle them and solve them effectively.

Sources of Variations

If employees are to know what to do and when then they must learn the contributing aspects of variation. These factors fall into six categories, called the 6 Ms These are Manpower, Methods, Machine, Materials, Measurements and Mother Nature (Environment).

Fishbone Examples

Wen Creating a fishbone diagram it is essential to determine the factors that contribute to a process.

Manufacturing Problems

5 Ms

- Method

- Mother Nature

- Man

- Machine

- Materials

6Ms

- Environment

- Equipement

- Method

- Material

- Measure

- Man

8 Ms

- Management / Money

- Measurement

- Material

- Machine (Tec)

- Maintenance

- Milieu / Environment

- Man Power

- Method

Marketing Problems

7Ps

- Processes

- People

- Place

- Product

- Physical Evidence

- Promotion

- Prices

8 Ps

- Product

- Place

- Price

- People

- Promotion

- Physical Evidence

- Process

- Performance

5 Ss

- Samples

- Schemes

- Synchronous

- Skin

- Search

Service Industries

- Suppliers

- Surroundings

- Systems

- Skills

Benefits of Fishbone Diagram

The process of creating a fishbone diagram helps ask why and brainstorm solutions.

Encouraging collaboration with joint brainstorming/ thought shower

Identify why something happens repeatedly at each stage.

Help identify underlying problems

Don’t be tempted to try and fix everything that might be causing the problem focus on the main cause.

Identifying Cause and Effect

The Fishbone Diagram is an effective approach for identifying cause and effect relationships. It can be used with the 5 Whys to find out root causes quickly. During brainstorming sessions to pinpoint problem causes, team members get to work together to learn the different challenges that need solving.