Ever wonder how we went from handcrafted goods to mass-produced everything? Enter Fordism — a production philosophy that changed not only how we build things, but how we live and work.

Named after Henry Ford, the visionary behind the Model T and the moving assembly line, Fordism revolutionised the manufacturing industry in the early 20th century. In this article, we’ll break down what Fordism is, its impact, and why it remains relevant today.

What is Fordism?

Fordism is a system of mass production and industrial management designed to maximise efficiency, lower costs, and make products accessible to the masses.

The core idea? Break production into small, standardised tasks performed repeatedly by specialised workers, powered by moving assembly lines.

Want to see where it all began? Check out our article on Henry Ford’s Assembly Line ➔

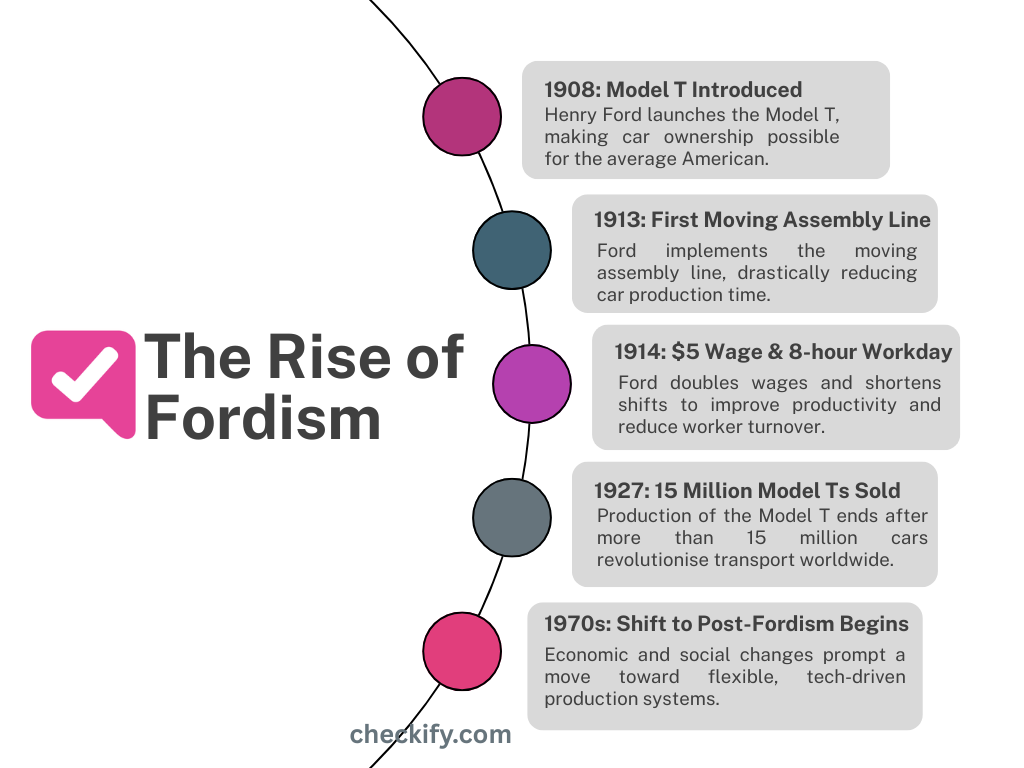

A Brief History: The Birth of Fordism

Before Ford’s innovations, production was mainly craft-based or employed early factory systems, where workers built entire items or worked in batches. Ford drew inspiration from meatpacking plants, where carcasses were transported along rails to butchers. By adapting this idea for car manufacturing and refining it with strict standardisation, Ford created the first true moving assembly line in 1913.

In 1913, Henry Ford introduced the moving assembly line to manufacture the Model T automobile. This innovation cut production time from over 12 hours to just 90 minutes per car!

This shift cut not only production time but also costs, allowing Ford to reduce the price of a Model T from $950 in 1909 to under $300 by the 1920s, making car ownership possible for the average American family.

Ford also believed that higher wages could lead to increased productivity. So, he doubled his workers’ pay and introduced the 8-hour workday — revolutionary ideas at the time.

- 1913: Ford’s Highland Park plant introduced the moving assembly line

- 12.5 hours ➝ 1.5 hours: Time to build a car before and after the assembly line

- $5/day: Ford’s famous wage offer, nearly doubling average factory pay

- 15 million: Model T cars sold by 1927

Together, these ideas created the blueprint for modern industrial economies.

The Core Principles of Fordism

Fordism was built on a simple but powerful idea: by breaking down production into smaller, repeatable steps and paying workers fairly, you could produce more, faster — and sell to the masses. Here are the four core principles that made it all work:

The Core Principles of Fordism

Here are the pillars that defined Fordism:

- Mass Production: Producing goods at scale using specialised machinery and workers

Goods are manufactured at scale using specialised machinery and streamlined processes. Instead of building one product at a time, Fordist factories could produce thousands quickly, consistently, and at an affordable cost. This shift transformed once-expensive items, such as cars, into everyday essentials. - Standardisation: Every product is made the same, ensuring quality and efficiency

Every product comes off the line the same. By standardising components and processes, Ford ensured that parts were interchangeable, quality was reliable, and production was ultra-efficient—no more custom fitting — just precision, speed, and consistency. - Division of Labour: Workers repeat specific tasks instead of building the whole product

Rather than crafting an entire product, workers specialise in one small, repeated task. This assembly-line method not only simplified training but also reduced production errors. It’s the classic “one person, one job” model that boosted output dramatically. - Higher Wages: Workers are paid well, so they can afford the products they build

In a bold move for the time, Henry Ford doubled his workers’ pay to $5 a day. His logic? If workers earned enough to buy the products they built — like the Model T — demand would grow, productivity would rise, and the whole economy would benefit. This was an early example of aligning labour and consumer power.

Why Fordism Was So Revolutionary

Fordism didn’t just change how factories operated — it transformed modern society. By combining efficiency, innovation, and a new approach to labour, Ford’s production model reshaped the economy, daily life, and even how people thought about work. Here’s why it was such a game-changer:

- Made Cars Affordable: The Model T became the first car that many working families could afford, turning automobiles from luxury items into everyday transportation.

- Boosted Productivity: Mass production techniques enabled factories to significantly increase output while reducing the time and cost required to manufacture each item.

- Stimulated Consumerism: Lower prices + higher wages = booming economy. The combination of lower prices and higher wages sparked a surge in consumer spending, helping to fuel a growing middle class.

- Redefined Work: The 8-hour workday and 5-day workweek became the new standard, shaping the modern 9-to-5 job structure still widely used today.

Fordism’s impact rippled far beyond the factory floor. It laid the foundation for consumer-driven economies, reshaped urban life, and established principles that still influence everything from retail and logistics to digital workflows. In short, it was nothing less than a revolution in how we live and work.

The Drawbacks of Fordism

While Fordism brought unprecedented efficiency and affordability, it wasn’t without its downsides. The same standardisation and structure that boosted productivity also introduced new challenges for workers and businesses. Over time, cracks began to show in the rigid system.

- Repetitive Work: Employees often performed the same task all day. Repetition led to boredom and burnout. Instead of feeling proud of crafting an entire item, workers performed a single task repeatedly, which some critics said turned humans into machines.

- Limited Innovation: Standardisation meant products were built to a strict template — which left little room for creativity, personalisation, or rapid innovation.

- Inflexibility: The system thrived on consistency, but struggled to adapt when markets shifted or customers demanded variety. Customisation and quick changes were difficult to implement in Fordist factories.

Fordism was brilliant in its time, but as the world became more dynamic and technology evolved, its rigid structure couldn’t keep up. These limitations eventually paved the way for new models of production — more flexible, people-focused, and adaptable to the changing needs of modern businesses and consumers.

Fordism vs. Post-Fordism

While Fordism was effective for decades, modern businesses require greater flexibility. Enter Post-Fordism, a newer model focused on customisation, decentralisation, and knowledge-based work.

By the 1970s, global economic changes, rising labour costs, and increasing demand for more personalised goods led to the decline of traditional Fordist models. The rise of computers, global supply chains, and information-based industries ushered in a more flexible, decentralised production model: Post-Fordism.

| Fordism | Post-Fordism |

|---|---|

| Mass production | Customised production |

| Standardised products | Personalised services |

| Centralised factories | Remote and global operations |

| Manual repetitive work | Automation and knowledge work |

| Fixed roles and tasks | Cross-functional, dynamic roles |

Where Fordism relied on scale, Post-Fordism values agility. It focuses on meeting niche demands through flexible production, decentralised teams, digital technologies, and highly skilled, multi-role workers. Think less factory belt, more cloud-based workflow.

Fordism’s Global Influence

Fordism spread far beyond Detroit. Countries around the world adopted elements of it to industrialise quickly.

- Europe: Following World War II, the post-war recovery employed Fordist principles to rebuild economies. In the UK and Germany, car factories and heavy industries followed the model.

- Soviet Union: While ideologically opposed to capitalism, the USSR adopted similar mass production techniques.

- Asia: Japan began with Fordist models but evolved them into Lean Manufacturing (a precursor to today’s Agile), adding continuous improvement and just-in-time systems.

Fordism and the Rise of Lean & Agile

Modern production systems like Lean, Six Sigma, and Agile software development trace their roots to Fordism. While they’ve evolved to be more flexible and people-focused, they still share Fordism’s emphasis on:

- Defined steps

- Efficiency

- Reducing waste

- Continuous improvement

Tools like Checkify take this legacy digital, turning complex processes into simple, repeatable workflows that teams can follow and improve. Whether you’re running a digital team or a physical business, the DNA of Fordism is in your checklist.

The Legacy of Fordism Today

You can still see Fordism’s influence in:

- Fast food chains: Standardised processes for efficiency

- Manufacturing plants: Assembly lines are still widely used

- Software development: Agile and lean methods have roots in Fordist efficiency

Even platforms like Checkify support the idea of simplifying and standardising processes, just like Ford did, but in a digital workspace.

Fordism and Process Management

Fordism laid the groundwork for modern process management and standard operating procedure by demonstrating how standardised workflows, division of labour, and clearly defined steps could dramatically improve efficiency and output. At the heart of Fordism was the idea of breaking down complex production into repeatable, manageable tasks—each performed in a specific sequence.

This mirrors the principles of process management today, where businesses map, monitor, and optimise workflows to ensure consistency, reduce waste, and enhance productivity. Whether you’re running a factory floor or managing digital workflows with tools like Checkify, the legacy of Ford’s systemised approach to production is still very much alive in how we manage processes today.

Process management. process improvement by breaking business tasks into small and more standardised processes that are simple to follow and optimised to give the best results every time.

Business processes are important because they are a step-by-step guide that describes how things are done in the best possible way and makes it easier to focus on improving business processes.

Read More: Why Business Process is Important

It’s your step-by-step plan for achieving your business goals.

Business process management is just like a recipe. It includes all the vital ingredients and instructions to take your important business activities from start to finish successfully and on time. But instead of a delicious chocolate cake at the end (unless you’re a bakery owner, of course), your finish line could be a product ordered and shipped to a satisfied customer.

Read More: No-nonsense guide to Business Process Management – and how it can make your business more awesome

Business processes are integral to the growth and success of any company. They set the blueprint or checklist for various activities, allowing employees to carry out small repeatable tasks towards a specific objective. Knowing what business processes are and developing them effectively are different things.

Read More: Business Process Management Benefits

Business process design should structure business processes into three types

Operational process

Supporting process

Management process

Read More: Business Process Design: Three Main Types